Exsolutione propriaPolyacrylamide(PAM) critical for achieving its optimal performance as a flocculant. Incorrecta praecepta ad clumpindum ("oculos piscium"), formationem gelum et moleculam degradationem, ineffectivom facientem.

Primus explicare gradus, intellegere principes fundamentales essent:

Rule "Slow Sprinkle & Fast Stir": PAM powder debet lentem et vespere aspergantur in aquam turbatum. Nunquam aquam in pulverem effunde, ut hoc causabit instantanium clumping quod est quasi impossibile dissolvere.

Velocitate Agitationis Control: Stirring provides the shear force needed for dispersion and dissolution.

Initial step: Vigorous stirring (approximately 300-600 rpm) to create a vortex that pulls the powder down and disperses it instantly.

Later Stage: After dissolution, reduce to gente stirring (approximately 40-60 rpm) to prevent the shear degradation of the long polymer chains.

Uter Neutral, Aqua munda: Aqua qualitate et temperatura crucial sunt.

Temperatura aquae: Aqua temperatura gazofilacionis ideal est. Slightly warm water (40-50°C) can accelerate dissolution, but temperatures nunquam 60°C excessivem debet quoniam degradationem thermali polymeri facient.

Qualitate aquae: Avoid using strongly acidic, alkaline, or high-salinity water unless specifically for treating such wastewater streams.

Preparation Concentration: Typically prepared as a 0.1% - 0.3% solutio stock (i.e., 1-3 grama PAM per litrum aquae). Altior concentrationes facient viscos, gel-like solutionem difficile manure et dilutere.

"Aging" Time: PAM require time to fully hydrate and activate. Solutione parata relinquetur "age" aut "maturing" pro 30-60 minutas post turbationem ut catenas polymeras maximas efficabilitatem pertinent.

Haec est modus maximus et recommendatus ad praeparationem laboratoriae et minoribus ad mediums.

Equipment necesse:

Dissolution tank (Suitable materials: stainless steel, plastic, or fiberglass to avoid corrosion)

Mechanical stirrer (velocitas adjustabilis valde recommendata est)

balance

Assignatio aquae

Instructiones graduum graduum graduum:

implete aqua: Fill the tank with the calculated volume of clean water (about 70-80% of the final desired volume).

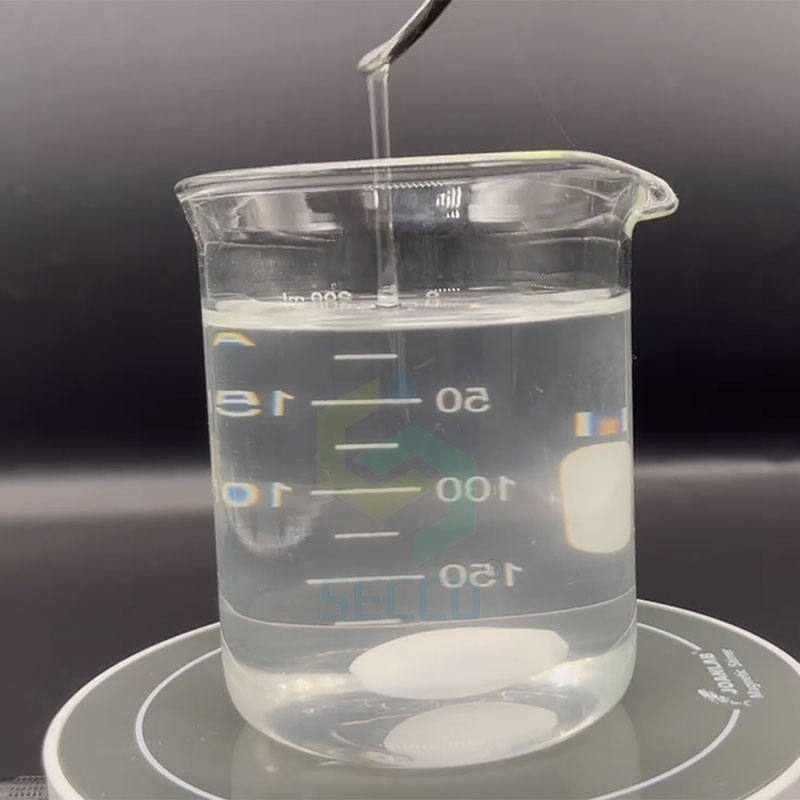

Initiate ferendum: Start the mixer at a medium-high speed (approximately 300-500 rpm) to create a strong, visible vortex in the water.

Pulver: Take the pre-weighed PAM powder and lentem et evenime efferge eam super superficiem et in vertex.

Critico: Pulvere fluent et in aquam individualis educetur, non in pulveres.

Continue stirring: Post omnem pulverem additum, continue stirring for minimo 30-60 minutas. Observe until the solution is uniform, clear, and free of any visible undissolved 颗粒 ("oculi piscium").

Superior et lens Stir: Once fully dissolved, add the remaining water to reach the final volume. Reduce velocitatem stirring a low (approx. 40-60 rpm) pluribus minutis homogeneitatem secure sine polymerum degradare.

Agiens: Turn off the mixer and let the solution stand (age) for minimum 30 minutis. The solution is now ready for use.

Pro magna magna aplicationes industriae systemae automatae preferuntur.

Automātica Dilution Online / Preparation Unit

Principle: This integrated system combines water feeding, dry polymer dosing, wetting, mixing, and aging in one unit. Venturi feeder or screw feeder draws and disperses PAM powder evenly into the water stream.

Adventationes: High automation, consistent and efficient dissolution, eliminates human error and clumping. Ideal for continuous feeding in water/wastewater treatment plants.

Manual Mixing (For very small quantities or emergencies only)

Method: Add water to a container, then slowly sprinkle PAM while vigorously stirring with a rode or a low-speed electric mixer.

Disadvantages: Labor-intensive, high risk of clumping, and often results in incomplete dissolution. Non recommendatus ad aplicationes critical.

PAM Anionic: Generally the easiest and fastest to dissolve.

Non-ionic PAM: Dissolves slightly slower than anionic PAM.

Cationic PAM: Due its positive charge and often higher molecular weight, it typically dissolves the slowest and is most sensitive to shear degradation. Use medium priority speed and nbsp;stirring speeds and nbsp;longe annos cationic PAM.

| Problema | Possible Cause | Solution |

|---|---|---|

| Clumping ("Eyes of Fish") | 1. Pulver çok hızlı ekledi. 2. Pul hala su atıldı. 3. Insufficient agitation | 1. Stop adding powder, crescere festinate velocitatem ut quaeret lumbos fregere. 2. Si gravis, discard batch. "Slow Sprinkle & Fast Stir" semper certa. |

| Low Viscosity / Poor Performance | 1. Insufficient dissolution/aging time 2. Excessive shear degradation from stirring 3. Temperatura aquae excelsa est 4. Product degradation or quality issue | 1. Ensure enough stirring and aging time. 2. Reduce agitation velocitatem post initium dissolutionem. 3. Temperatura cubicula aut aqua luxuria utilizat (<50°C). 4. Check product shelf life and storage conditions. |

| Solution Stratifies (Layers) | phenomeno normale, maxime post longum stantem. | Gently stir before use. Premissi sunt praeparare solutiones fresces et inter 24 horas utilizati. |

Praecepta maxima Mantra:

Vortex in aqua, pulverem lentem aspersit,

Tenite ergo molle, polymer crescet.

Temperatura gazofilacia optima est, evade calore,

Agiens actionem puram facit.

Si volueritis ad produktos nostros aut habere quaestiones, implete formam inferiorem, quaeso. We will contact you immediately after receiving it. Thank you for your choice.