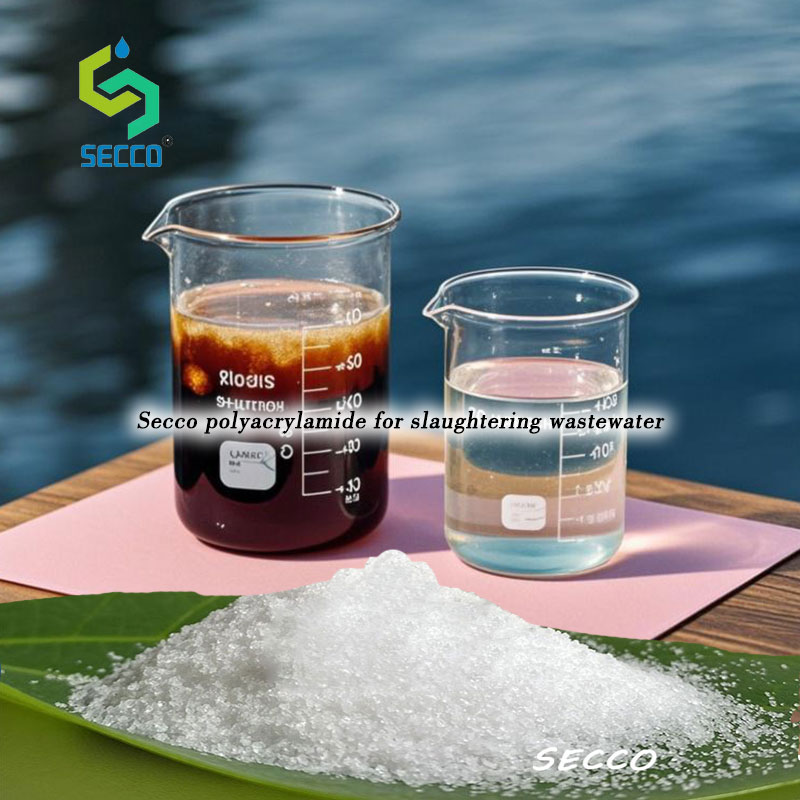

Wastewater from slaughterhouses is difficult to treat a cause of its high concentration of organic matter, suspended solids (such as blood, grease, hair, internal organ debris, etc.) and strong fishy odor. Polyacrylamide (PAM), as an efficient high-molecular flocculant, plays a significant role in the treatment of slaughterhouse wastewater. Hoc articulum elaborabitur in aspectis, quales characteres aquae desertae, mechanismus action of PAM, key points for selection, treatment processes, and case analyses.

I. Characteristics and Treatment Difficulties of Slaughterhouse Waste

Aquae qualitate complex a est: Aquae wastewater continet multam substantiam organicam, quam proteinum, adipem et sanguinem, cum extremely high COD (Chemical Oxygen Demand) et BOD (Biochemical Oxygen Demand), et etiam oleum continet, solidos suspendentes, et minorem magnitudinem metallorum ions.

Biodegradabilitate forta sed fluctuationes magnas: Wastewater habet bonam biodegradabilitatem, sed aquae qualitatem et quantitatem significantem influentur a factoribus, quales volumen occisionis et season. The treatment process needs to have strong adaptability. 69.

High viscosity and color: The wastewater is red-brown in color and has a relatively high viscosity, which limits the efficiency of traditional physical sedimentation or biological treatment.

Ii. Mechanism of Action of Polyacrylamide

Polyacrylamide purificationem aquarum desertorum per sequentes mechanismos accipit:

Adsorption bridging effect: The long-chain structure of PAM can adsorb suspended particles, form large flocks, and accelerate solid-liquid separation.

Charge neutralisation: PAM Cationic neutralizet particulas colloidales negativo accusatos per cargam positivam, reducit force repulsionis et promovit flocculationem.

Reductione vitae et resistentiae: PAM potest reddere viscositatem aquarum wastorum et meliora operativam effectivitatem unitatis subsequentum tractionis (sicut transportatio pipeline et flotation aeris) per 57%.

Iii. Selection and Application Points of Polyacrylamide

Selection

Tips Anionis (APAM): Est adequat wastewater cum pH neutrale aut alkaline, particular in casibus minimis saturis olei. It is often used in combination with inorganic coagulants (such as polyaluminium chloride PAC) to enhance the removal rate of suspended solids by 26%.

Cationic type (CPAM) : Optimum est aquae desertae olei altissimi et wastewater cum particibus colloidis negativo charged. It can effectively remove COD and decolore, and is especially suitable for enhanced treatment in low temperature environments in winter.

Molecular weight and ion degree: High oil wastewater requires PAM with high molecular weight and low ion degree. Quando magnus volumen aquae est, elige produktos cum minore pondo moleculari et alto degree ion.

2. Methodus Dosage and dose optimization

Modellum optimum et dosage (normale 0.1-0.3% solutionem) per minore testos laboratorium determinare debet ut non excessivem dissipationem aut maiorem constitueret.

Sugerit ut in combination cum coagulantibus, sicut PAC "coagulation-flocculation" synergisticum effectum synergisticum faceret, et effectum tractionis ad 78 meliorare.

Iv. Typical Processing Techniques and Case Analysis

1. Physical-chemical and biochemical combined process

Gravitas pretreationis: Gravitas magnas impuritates particularum intercept, tancus regulator homogenizat et equitat volumen, apparatus aeris flotacionis PAC et PAM addet ut auferat oleum et solidos suspendentes, et fluctus COD excessit 30%.

Physical treatment stage: The hydrolysis acidification tank decomposes large-molecule organic substances in small molecules, and then further degrades them through the A/O process (anaerobic-aerobic). Finally, the standard discharge is achieved through chlorine dioxide oxidation or membrane separation technology.

2. Case reference

Case of a slaughterhouse in Henan Province: The process of "air flotation + anionic PAM+ hydrolysis acidification + contact oxidation" was adopted, with the removal rate of suspended solids reaching over 90%, and the COD of the effluent was reduced to below 100 mg/L, meeting the "Discharge Standard of Water Pollutants for Meat Processing Industry" 78.

Treatment plan for low-temperature environments in the north: In winter, add enhanced cationic PAM and combine it with Fenton oxidation technology to effectively solve the problem of low microbactivity at low temperature and ensure stable treatment effects.

V. Precautions and Future Directions

Teste primum: Model PAM determinatus est per testes beaker et testes pilot in site ut non directo applicet solutionem generalem 28.

Comprehensive treatment technology: PAM has a limited effect on the removal of heavy metals and needs to be combined with chemical precipitation, adsorption or membrane technology to achieve comprehensive purification.

Sludge disposition: The sludge produced by flocculation needs to be dewater (such as through plate and frame filter press) for resource use to reduce secondary pollution by 78%.

In the future, with the increasing environmental protection requirements, the modification research of PAM (such as the improvement of salt resistance and shear resistance) and its integration with intelligent control systems will further enhance the efficiency and sustainability of slaughterhouse wastewater treatment.

Through reasonable selection and process optimization, polyacrylamide has demonstrated remarkable economic and environmental benefits in the treatment of slaughterhouse wastewater, providing important technical support for the industry to achieve green production.

Si volueritis ad produktos nostros aut habere quaestiones, implete formam inferiorem, quaeso. We will contact you immediately after receiving it. Thank you for your choice.