Lɔ̈ɔ̈i path ofPolyacrylamide (PAM) ee kë thiekic bï yen luui apath cït flocculant. Lɔ̈ɔ̈m ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈

Ka tɛ̈n cï yïn kä ye kek looi ya tɔ̈ɔ̈u thïn, ka tɛ̈n cï yïn kä ye kek looi ya tɔ̈ɔ̈u thïn:

"Slow Sprinkle & Fast Stir" RulePAM powder A dhil a tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n. Lɩk pi tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈uLɔnadɛ̈ yen bɛ̈n looi bɛ̈n ya cɔk tɔ̈ɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ

Kɔntrol Agitation Speed: Kɔc ye kek cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk.

Fɛɛr fɔlɔ: A duniŋ ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔ

Ye raan : Na cï yen tɔ̈ɔ̈u, ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈ulaŋgɛ ye kek cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk

Luɔ̈ɔ̈i Pii, Pii Pii: Pii cï kek ya looi ku jɔl ya tɛ̈ɛ̈r cï kek ya looi aye thiekic apɛi.

Pii Temperature: Pii pip tɛmɛri duëël a ye kë puɔth ye. Pii dɔ̈ɔ̈r (40-50°C) lëuye cɔl dissolution accelerate, ku tɛ̈ɛ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r dɔ̈ɔ̈r 60°C cïmën bï kek polymer ya cɔk tɔ̈ɔ̈u.

Water Quality (Pii): Yïn tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈

Luɔ̈ɔ̈i Concentration: Yïn aye looi ke ye 0.1% - 0.3% Kä ye kek tɔ̈ɔ̈u thïn (cïmën de, 1-3 gram PAM në litre de pi tök). Kä ye kek tɔ̈ɔ̈u nhial abï kä ye kek tɔ̈ɔ̈u nhial ya cɔk tɔ̈ɔ̈u nhial, kä ye kek tɔ̈ɔ̈u nhial ye kek tɔ̈ɔ̈u nhial ye kek tɔ

"Lɛ̈k" WaktuPAM wïc kaam bï yen ya cɔk lɔ̈ɔ̈m ku bï ya cɔk lɔ̈ɔ̈m. Lɔ̈ɔ̈i cï looi adhil bɛ̈n ya tɔ̈ɔ̈u "age" wala "maturing" ago 30-60 minit tɛ̈n yenë kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc ye kɔc

Yen ee tɛ̈n yenë kɔc juëc ye luɔ̈ɔ̈i thïn në laboratory ku jɔl ya tɛ̈n yenë kɔc ye luɔ̈ɔ̈i thïn në tɛ̈n yenë kɔc ye luɔ

Kä wïc:

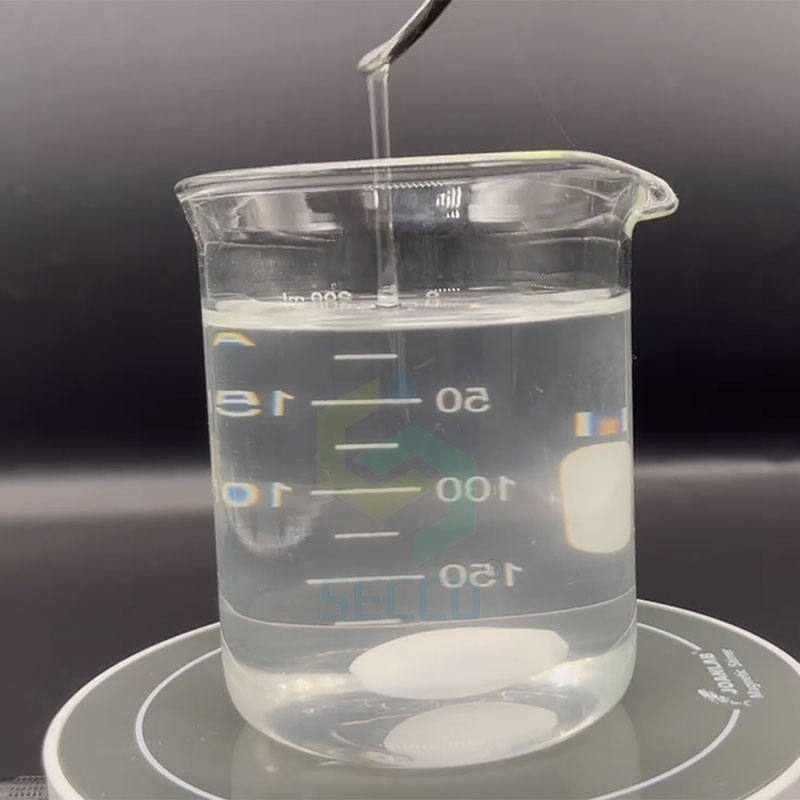

Tank ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k

Mechanical stirrer (speed adjustable is highly recommended) (Mechanical stirrer) (speed adjustable is highly recommended) (Mechanical stirrer) (speed adjustable is highly recommended)

Balance wɛ̈t

Pii tɔ̈u

Lööŋ ye kek looi:

Lɔ̈k kɛ pi: Lɩzɩ koom ye kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ kɩ-tɛ

Lɔ̈k kɛ̈ɛ̈r: Start mixer at a medium-high speed ((ye 300-500 rpm) bï kɔc ya cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk c

Piksa Powder: Lɔ PAM powder cï kek tɔ̈ɔ̈u thɛɛr ku ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye kɛ̈ɛ̈k ye y'a tɛ̈ɛ̈r piny ku tɛ̈ɛ̈r piny.

Critical ye: Pɔɔr dɔ adhil bɛ̈n lɔ̈ɔ̈m ku bɛ̈n lɔ̈ɔ̈m pi kɔnɔ, ka tɛ̈n tɔ̈ɔ̈u.

Continue stirring : Na cï puɔ̈ɔ̈r bɛ̈ɛ̈i mat, tɛ̈ɛ̈m tɛ̈ɛ̈m tɛ̈ɛ̈m tɛ̈ɛ̈m30-60 minitLɩk tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n 颗粒 (("kuɛl pipi").

Top Up ku Slow Stir : Na cï yen tɔ̈ɔ̈u, ka pii dɔ̈ɔ̈r tɔ̈ɔ̈u bï yen tɔ̈ɔ̈u. Lɔ̈k tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈rlow ye ((approx. 40-60 rpm) në minit juëc kɔ̈k ago kɔc cï gam ya cɔk loi rot në polymer kënë yic.

Kɔl: Lɔ̈k mixer la lɔ̈k solution tɔ̈u (run) tënë 30 minitKä ye kek looi acï rot looi.

Kɛ kui̱i̱ luɔɔi kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl-kɛl

Automatic Online Dilution / Preparation Unit (Automatic Online Dilution / Preparation Unit)

Prinsip: Sisitɛm kënë ye kɔc cɔl water feeding, dry polymer dosing, wetting, mixing, and aging në unit tök. Venturi feeder wala screw feeder ye PAM powder bɛ̈n tɔ̈ɔ̈u ku bɛ̈n tɔ̈ɔ̈u në pïïr yic.

Fɛɛr: Automation dɔ̈ŋ, tɛ̈n yenë rot looi ku tɛ̈n yenë rot looi, ye raan cï rot looi ku tɛ̈n yenë rot looi. A path bï kɔc ya cam tɛ̈n yenë kɔc ya cam tɛ̈n yenë kɔc ya cam tɛ̈n yenë kɔc ya cam tɛ̈n yenë kɔc ya cam

Manual Mixing (Kɛ kui kä thiin koor wala kä ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k ye kɛ̈k)

Metod : Lɔ̈k pi në kɔc dɔ̈ɔ̈r yic, ku jɔl ya PAM ye cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk.

Disadvantages : Luɔi wʋsg, kä juëc ye kek tɔ̈ɔ̈u, kä ye kek tɔ̈ɔ̈u, kä ye kek tɔ̈ɔ̈u, kä ye kek tɔ̈ɔ̈u. Ka raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan kɛ kui̱i̱ kä thiekic.

Anionik PAM: A yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic a yic.

PAM non-ionik: A cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔ

PAM katiyonik : A ye tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë t Luɔi piny tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈rye dɔŋ thaa cï rot looi tënë cationic PAM.

| Problɛm | A lëu yen | Solution |

|---|---|---|

| Clumping ("Fish Eyes") | 1. Powder cï bɛ̈n juak pɛ̈th 2. Powder ye tɔ̈ɔ̈u piny 3. Ka tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n | 1. Stop ka powder, juak ye tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈ 2. N'a tɛ̈ɛ̈r, ka tɛ̈ɛ̈r. Lɛ̈k "Slow Sprinkle & amp; Fast Stir". |

| Low Viscosity / Bad Performance | 1. Ye tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n 2. Kä ye kek cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk cɔk 3. Pii tɔ̈u nhial 4. Kä ye kek looi ka kä ye kek looi | 1. Lɔ̈k ba tɛ̈n yenë kɔc rɔ̈ɔ̈r ku kɔc rɔ̈ɔ̈r looi. 2. Lɔ̈k tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r tɛ̈ɛ̈r. 3. Luɔ̈ɔ̈i tɛ̈ɛ̈r tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u tɔ̈u 4. Cɔl tɛ̈n yenë kä ye kek tɔ̈ɔ̈u thïn ku tɛ̈n yenë kek tɔ̈ɔ̈u thïn. |

| Solution Stratifies (Layers) | Kë cï rot looi aye rot looi, tɛ̈n yenë kɔc tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u ye tɔ̈ɔ̈u. | Lɔ̈ɔ̈m ka tɛ̈ɛ̈r ka tɛ̈ɛ̈r ka tɛ̈ɛ̈r ka tɛ̈ɛ̈r. A puɔ̈l bï yïn kä yam looi ku luɔ̈ɔ̈i në thaa 24 yiic. |

Mantra ë luɔɔi path:

Wɛɛr dɔ̈ɔ̈r, puɔ̈ɔ̈r dɔ̈ɔ̈r, puɔ̈ɔ̈r dɔ̈ɔ̈r,

Lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k lɔ̈k.

Room temperature is best, avoid the heat,

Kɔc dɔ̈ɔ̈r ye kɔc dɔ̈ɔ̈r ye kɔc dɔ̈ɔ̈r ye kɔc dɔ̈ɔ̈r ye kɔc dɔ̈ɔ̈r.

Na yïn wïc ba kä ye kek looi ya tɔ̈ɔ̈u, ka yïn naŋ thiëëc kɔ̈k, ke yï lɛ̈k form tɔ̈u piny. Ɣok abï yïn thiëëc tɛ̈n yenë yïn yök.